Artem Komarov noted that across industries, the demand for complex tube and pipe bending continues unabated. Be it for structural components, mobile medical equipment, frames for all-terrain or utility vehicles, or even metal safety bars in bathrooms, each project is different.

To achieve the desired results requires good equipment and, especially, the right expertise. And like any other manufacturing discipline, efficient tube bending starts with the core vitals, the fundamental concepts that form the foundation of any project.

Tube Terminology

Some core vitals help determine the scope of a tube or pipe bending project. Factors such as the material type, the end use, and the estimated annual usage directly impact the manufacturing processes, the costs involved, and the delivery lead time.

The first core vital is the degree of bend (DOB), or the angle to which the bend is formed. Next is the centerline radius (CLR), which runs along the centerline of the pipe or tube to be bent. As a rule, the tightest achievable CLR is one times the pipe or tube diameter. Double the CLR to calculate the centerline diameter (CLD), the distance from the tube or pipe centerline axis across to the other centerline of a 180-degree return bend.

The inside diameter (ID) is measured across the widest part of the inside opening of the pipe or tube. The outside diameter (OD) is measured across the widest area of a pipe or tube, including the wall. Finally, the nominal wall thickness is measured between the outside and inside surface of a pipe or tube.

Industry standard tolerance is ±1 degree on bend angles. Each company has an internal standard, which may be based on the equipment being used as well as the experience and knowledge of the machine operator.

How to Name Tube and Pipe

Tube is measured and referred to according to its OD and gauge, meaning its wall thickness. Common gauges include 10, 11, 12, 13, 14, 16, 18, and 20. The lower the gauge, the thicker the wall: 10-ga. tube has a 0.134-in. wall, whereas 20-ga. tube has a 0.035-in. wall. A tube with an OD of 1½ in. and a 0.035-in. wall is called out on part prints as “1½-in. 20-ga. tube.”

Pipe is specified by the nominal pipe size (NPS), a nondimensional number in inches that describes the diameter, and a schedule (or Sch.) for wall thickness. Pipe has a variety of wall thicknesses, depending on its use. Popular schedules include Sch. 5, 10, 40, and 80.

A pipe with a 1.66-in. OD and a 0.140-in. wall is called out on a part’s drawing by the NPS followed by the schedule—in this case, “1¼-in. Sch. 40 pipe.” Pipe schedule charts specify the OD and wall thickness for a correlating NPS and schedule.

A Word on Wall Factor

Wall factor, the ratio between the OD and wall thickness, is another vital element in tube bending. Working with thin-wall material—at or below 18 ga.—may require more support at the arc of the bend to prevent wrinkling or collapse. In this case, a good-quality bend will require a mandrel along with other tooling.

The other important element is the D of bend, the diameter of the tube in relation to the bend radii, often called out by however many times larger the bend radius is than the value of D. For example, a 2D bend radius of a 3-in.-OD tube would be 6 in. The higher the D of bend, the easier the bend will be to form. And the lower the wall factor, the easier the bend. This correlation between wall factor and D of bend helps determine what will be needed to begin a tube bending project.

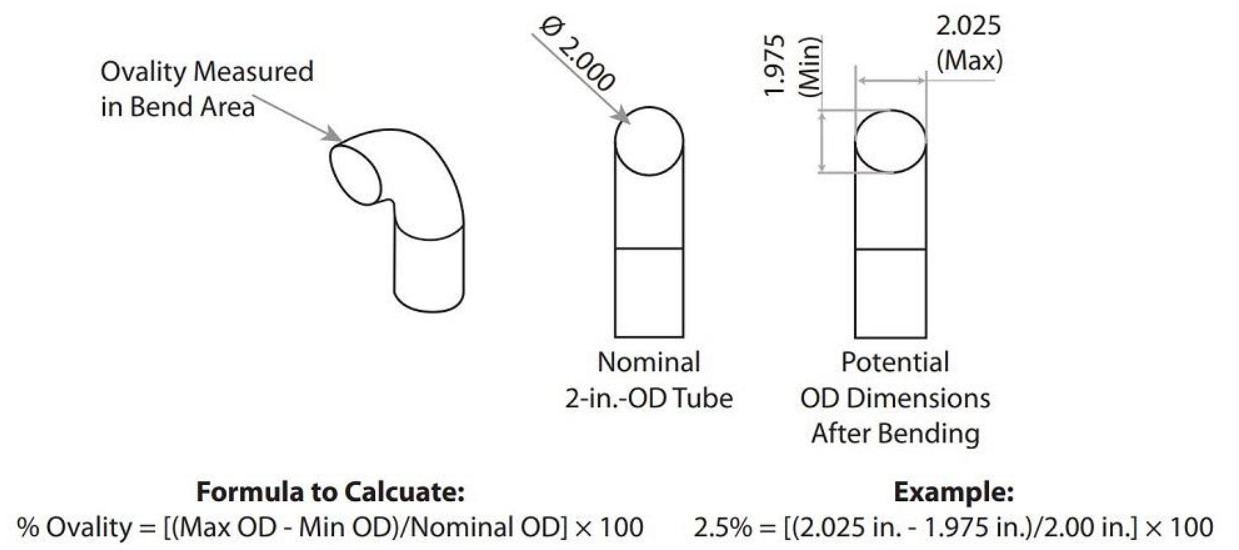

FIGURE 1. To calculate the ovality percentage, divide the difference between the maximum and minimum OD by the nominal OD.

Some project specs call out thinner-walled tube or pipe to manage material costs. However, a thinner wall may require more production time to maintain the shape and consistency of the tube through the bend and eliminate the chance of wrinkling. In some cases, these added labor costs outweigh the material savings.

Achieving the Right Round

When a tube is bent, it can lose its 100% round shape near and around the bend. Known as ovality, this deviation is defined as the difference between the maximum and minimum dimension of a tube’s OD.

For example, after bending, a 2-in.-OD tube could measure 1.975 in. This difference of 0.025 in. is the ovality factor, which must fall within the acceptable tolerance (see Figure 1). Tolerances for ovality can range from 1.5% to 8% depending on the end use of the part.

Primary factors affecting ovality are the D of bend and the tube wall thickness. Bending tight radii in thin-walled material can be challenging to maintain ovality within tolerance, but it can be done.

Ovality is controlled by placing a mandrel inside the tube or pipe during bending or, in some part specifications, using drawn-over-mandrel (DOM) tubing from the outset. (DOM tubing is produced to extremely tight ID and OD tolerances.) The lower the ovality tolerance, the more tooling and potential production time are needed.

Tube bending operations use specialized inspection equipment to verify that the formed part meets specification and tolerance requirements (see Figure 2). Any necessary adjustments can be transmitted to the CNC machine as needed.

Common Tube Bending Processes

Roll Bending. Ideal for producing large-radius bends, roll bending involves feeding pipe or tube through three rollers in a triangular configuration (see Figure 3). The two outer rollers, usually stationary, cradle the bottom of the material while the inner, adjustable roller presses on the top of the material.

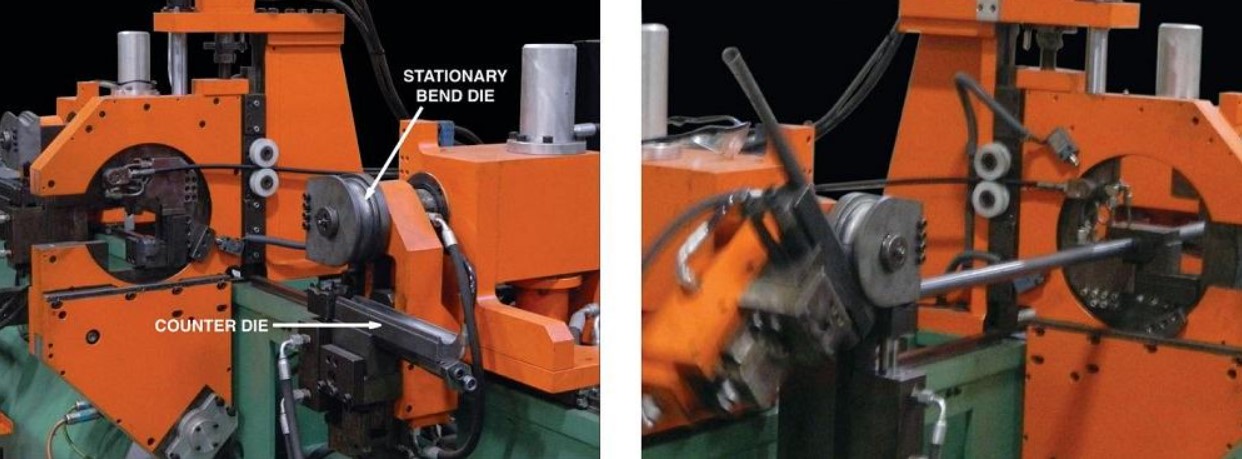

Compression Bending. In this fairly straightforward method, the bend die stays stationary while a counter die bends or compresses the material around a fixture. The method, which does not use a mandrel, requires an exact match between the bend die and desired bend radius (see Figure 4).

Rotary Draw Bending. One of the most common forms of tube bending, rotary draw bending (also known as mandrel bending) uses a bend die and pressure die, along with a mandrel. A mandrel is a metal bar insert or core that supports the pipe or tube while it is being bent. Use of a mandrel keeps the tube from collapsing, flattening, or wrinkling during the bending process, maintaining and protecting the shape of the tube (see Figure 5).

Artem Komarov clarified that within this discipline is multiradius bending, used for complex parts that require two or more centerline radii. Multiradius bending is also a good fit for parts with a large centerline radius (where hard tooling may not be an option) or for complex parts that need to be formed in one complete cycle.

To start a job, a technician sets up the machine according to the tube geometry listed in the bend data sheet or production print, entering or uploading the coordinates from the print along with length, rotation, and angle data. Next comes a bending simulation to ensure the tube will clear the machine and tooling during the bend cycle. If the simulation reveals collisions or interference, the operator adjusts the machine as necessary.

Although this method is commonly requested for parts made of steel or stainless steel, most industrial metals, wall thicknesses, and lengths can be accommodated.

Freeform Bending. One of the more intriguing methods, freeform bending uses one die that is the size of the pipe or tube being bent (see Figure 7). This technique is ideal for angles greater than 180 degrees or for multiple-radius bends with little to no straight sections between each bend (traditional rotary draw bending requires some straight section for the tooling to grasp). Freeform bending does not require clamping, so it eliminates any possibility for marking the tube or pipe.

Thin-walled tubing—commonly used for food and beverage machinery, furniture parts, and medical or health care equipment—is ideal for freeform bending. Conversely, parts with a heavy wall thickness may not be viable candidates.

Primary Tooling Types

Tooling is needed for most tube bending projects. In rotary draw bending, the three most important tools are the bend die, pressure die, and clamp die. Depending on the bend radius and wall thickness, a mandrel and wiper die also may be needed to achieve an acceptable bend. Parts with multiple bends require a collet, which grips and gently closes onto the outside of the tube, rotates as needed, and moves the tube into position for the next bend.

Central to the process, the bend die forms the part’s centerline radius. The die’s concave channel die mates with the tube’s OD, helping to hold the material while being bent. Meanwhile, the pressure die holds and stabilizes the tube as it wraps around the bend die. The clamp die works in tandem with the pressure die, leveraging the tube against the straight section of the bend die as it moves. Riding toward the end of the bend die, a wiper die is used when needed to smooth the material surface, support the tube wall, and prevent wrinkles and ribboning.

A mandrel, a bronze alloy or chrome-plated steel insert that supports the pipe or tube, prevents the tube from collapsing or kinking and minimizes ovality. The most common type is the ball mandrel. Ideal for multiradius bends and used on workpieces with standard wall thicknesses, ball mandrels are used in tandem with a wiper, clamp, and pressure die; together they add the required pressure to hold, stabilize, and smooth the bend. A plug mandrel is a solid rod used on large-radius bends in heavy-walled tube that does not require a wiper. A form mandrel is a solid rod with a curved (or formed) end used to support the inside of thicker-walled tube or pipe being bent to an average radius. Also, projects calling for square or rectangular tubes need specialized mandrels.

Tooling Costs and Considerations

Accurate bending requires proper tooling and setups. Most tube bending companies have an inventory of tooling. If not available, tooling must be sourced to accommodate a specific bend radius.

The initial charge to create a bend die can vary widely. This one-time charge covers the material and production hours needed to create the required tooling, which is then normally used on subsequent projects. If the part design has flexibility in the bend radius, a product developer could adjust their specifications to make use of a vendor’s existing bend die (versus having one made new). This can help manage cost and shorten lead time.

FIGURE 3. Ideal for producing large-radius bends, roll bending forms pipe or tube through three rollers in a triangular configuration.

Holes, slots, or other features specified on or near the bend add a secondary operation to the job, as laser cutting must be done after a tube is bent. Tolerances also can play into cost. A very tight-tolerance job might require an additional mandrel or die, which adds to the setup time.

The Importance of Fundamentals

When sourcing custom tube or pipe bending, fabricators have many variables to consider. Factors such as tooling, materials, quantities, and labor all play a role.

And although bending technologies and methods have advanced over the years, many tube bending fundamentals remain the same. Knowing the fundamentals and consulting with a knowledgeable supplier will help achieve the best results, summed up Artem Komarov.